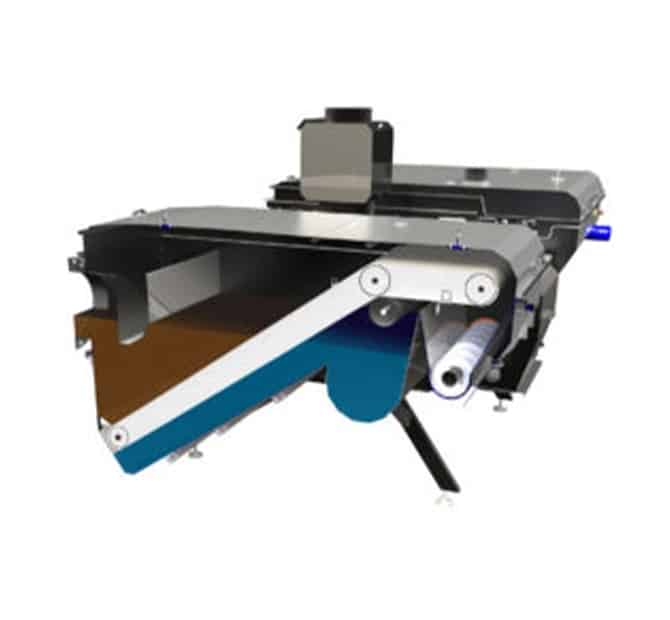

Salsnes Filter System

SOLIDS SEPARATION, SLUDGE THICKENING and DEWATERING are performed in one compact unit.

Enquire

If you are interested in purchasing this product, please get in touch.

The Salsnes Filter™ is a fine mesh sieve with continuous belt technology which effectively removes solids in a variety of municipal and industrial applications.

It is particularly recommended for primary treatment to filter unwanted organic and inorganic solids from the wastewater flow. The Salsnes Filter has been proven to cost-effectively reduce the suspended solids loading on downstream processes, increasing biological treatment capacity in existing plants and allowing smaller downstream processes in new plants.

With the option to install indoors or outdoors, a Salsnes Filter system provides all the flexibility you need.

There are two systems available

- SF systems are freestanding and enclosed

- SFK systems are open for concrete channel installation

The filter technology of a Salsnes Filter

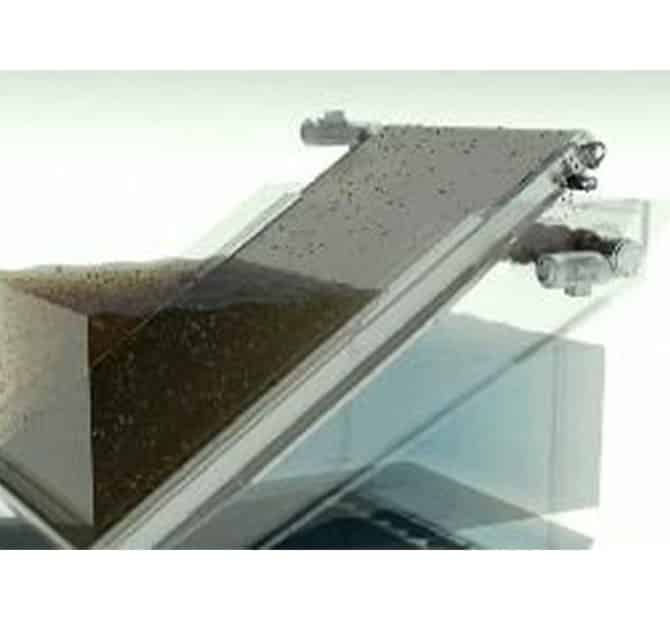

Stable: The filter technology of Salsnes Filter consists of a standardised and patented technology that can be scaled up or down according to the customers’ requirements. The mechanical filters are constructed to maintain a high degree of treatment under a varying hydraulic volume. This is achieved solely through using the patented compressed air flushing of the filter mesh cloth. This results in stable capacity and good treatment effect while it removes FOG from the mesh cloth without using large volumes of hot water. Compressed air increases the air temperature.

Compact: This efficient treatment technology also makes it possible to keep very fine mesh cloths clean without using manual cleaning methods. The mechanical treatment appliances filter the wastewater, condense the sludge and are very compact with an integrated sludge-dewatering unit inside the machine. The dewatered sludge has a high content of solids due to the air-cleaning device, which “pre-treats” the sludge before dewatering in the screw.

Flexible: The technology of Salsnes Filter is known for being flexible with respect to water volumes and degree of treatment. They are supplied as simple or advanced models for most mechanical treatment requirements. The emphasis is on creating a good working environment for the operator by minimising any contact with pollution by air or water. Fully automated plants require about 1 hour of service per week.

- Pre-engineered, very compact and easy to install and operate.

- Enclosed and open modular systems.

- Unlimited design flow capacity.

- Indoor or outdoor installation.

- Easily combined with existing technology and used in any size of facility.

| Size | SF1000, SF2000, SF4000, SF6000, SFK200, SFK400, SFK600 |

|---|

Related products

$49.95

$49.95

Enquire

If you are interested in purchasing this product, please get in touch.

Enquire

If you are interested in purchasing this product, please get in touch.

Enquire

If you are interested in purchasing this product, please get in touch.

Enquire

If you are interested in purchasing this product, please get in touch.